Solución de robot de fundición Abb

Solución de robot de fundición Abb:

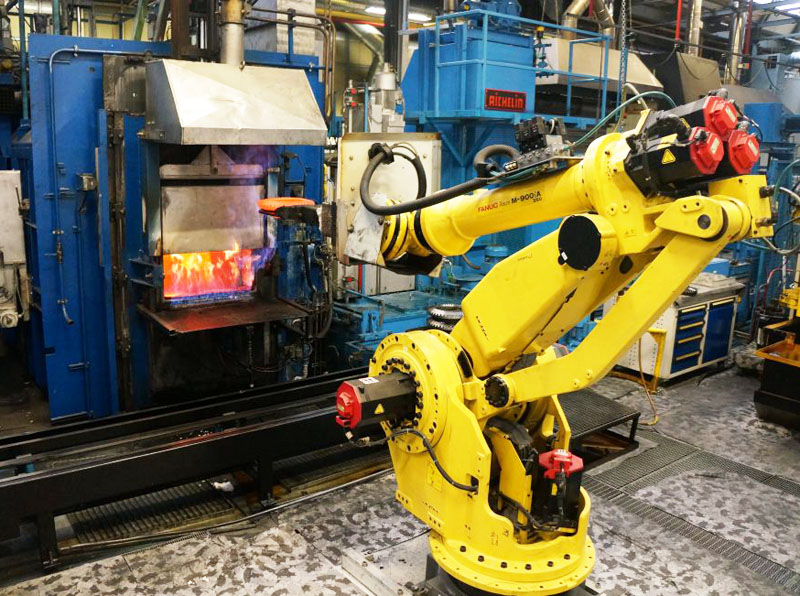

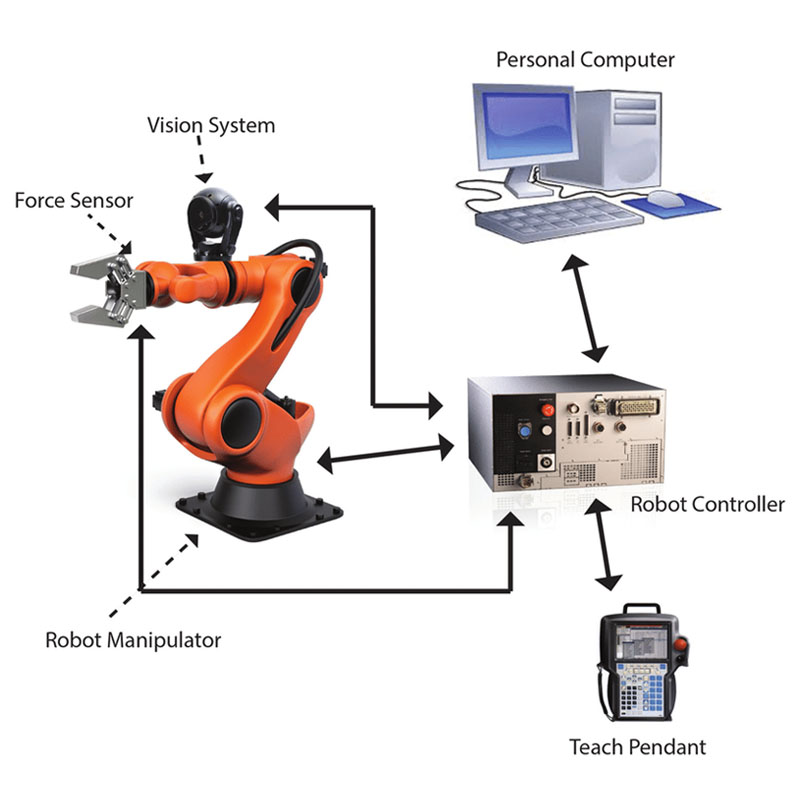

1. Capacidades de automatización avanzadas: los robots de fundición de ABB están equipados con capacidades de automatización avanzadas, lo que les permite manejar tareas complejas con precisión y exactitud. Pueden realizar tareas como verter metal fundido, manipular componentes pesados y manipular moldes con facilidad.

2. Seguridad de los trabajadores mejorada: los robots de fundición de ABB ayudan a minimizar el riesgo para los trabajadores humanos en entornos de fundición peligrosos. Pueden realizar tareas en temperaturas extremas, trabajar en espacios reducidos y manejar cargas pesadas, lo que reduce la probabilidad de accidentes y lesiones.

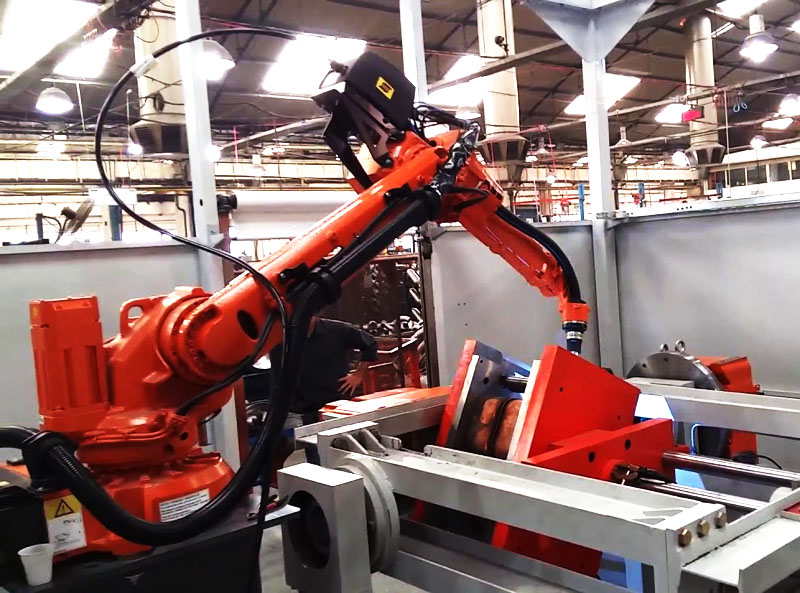

3. Productividad y eficiencia mejoradas: los robots de fundición de ABB mejoran enormemente la productividad en las operaciones de fundición. Pueden trabajar continuamente sin interrupciones, lo que aumenta las tasas de producción y reduce los tiempos de ciclo. Sus movimientos rápidos y precisos permiten un flujo de trabajo eficiente y optimizado en la fundición.

Comuníquese con nosotros para obtener parámetros técnicos detallados.

Solución de robot de fundición Abb:

Los robots de fundición ABB se utilizan principalmente en industrias para tareas como manipulación de materiales, mantenimiento de máquinas, fundición, fundición a presión y soldadura por puntos. Están diseñados para soportar entornos hostiles y de alta temperatura. Estos robots aumentan la productividad, mejoran la calidad y mejoran la seguridad en el lugar de trabajo. También se utilizan en la industria automotriz para tareas como montaje, pintura y soldadura. Los robots de fundición de ABB también son capaces de realizar tareas más complejas, como la impresión 3D, con precisión y exactitud. Están diseñados para ser flexibles y versátiles para adaptarse a una variedad de aplicaciones industriales.