Solución de robótica en fundición

Solución de robótica en fundición:

1. Mayor eficiencia: la robótica en las fundiciones puede mejorar en gran medida la eficiencia al automatizar tareas como el manejo de materiales, el vertido y el acabado. Los robots pueden trabajar a un ritmo constante sin interrupciones ni fatiga, lo que permite una producción más rápida y tiempos de ciclo reducidos.

2,Mejor seguridad de los trabajadores: las operaciones de fundición pueden ser peligrosas y exponen a los trabajadores a altas temperaturas, equipos pesados y materiales peligrosos. El uso de robots en la industria de la fundición puede ayudar a minimizar estos riesgos al realizar tareas peligrosas, reduciendo la probabilidad de accidentes y lesiones a los trabajadores humanos.

3. Precisión y exactitud mejoradas: los robots en las fundiciones pueden realizar tareas con un alto nivel de precisión y exactitud. Pueden verter con precisión metal fundido en moldes, manipular y posicionar piezas de manera consistente y realizar complejas tareas de acabado. Esto da como resultado una mejor calidad de la fundición y reduce el riesgo de defectos o inconsistencias.

Comuníquese con nosotros para obtener parámetros técnicos detallados.

Solución de robótica en fundición:

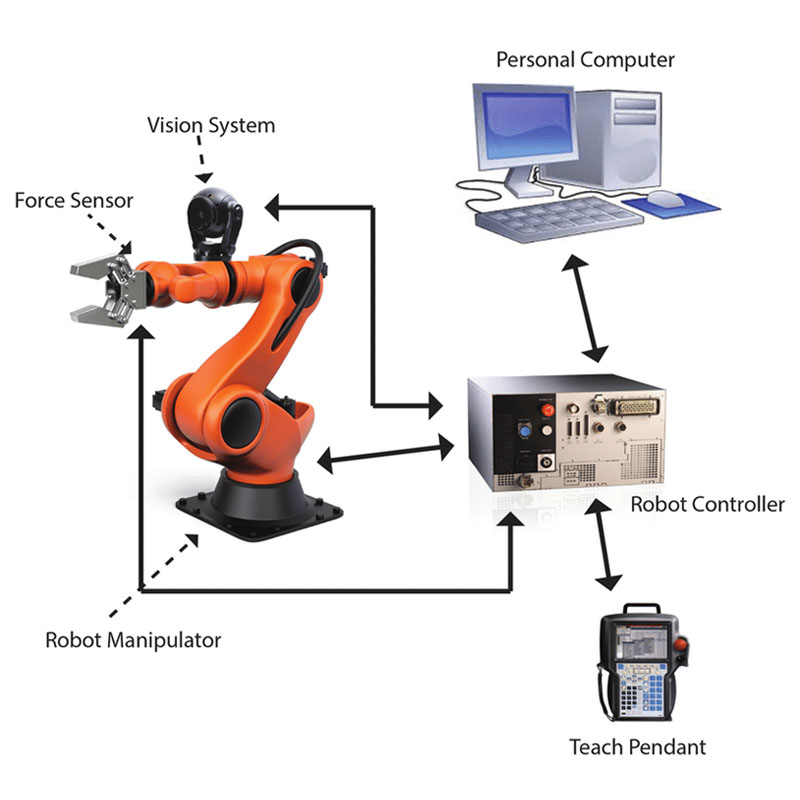

La robótica en aplicaciones de fundición ha revolucionado la industria manufacturera. Solución de Robótica en Fundición en nuestra empresa poder Ahorre 92% en el costo. de una patrulla tripulada. Comuníquese con nosotros para obtener parámetros técnicos detallados. Los robots se utilizan para tareas como fundición, moldeado y acabado, lo que reduce la participación humana y aumenta la eficiencia y la precisión. Pueden soportar condiciones duras, incluidas altas temperaturas y polvo, lo que garantiza una calidad de producción constante. Los robots también mejoran la seguridad al realizar tareas peligrosas y minimizar las lesiones en el lugar de trabajo. Además, son programables y se pueden personalizar para cumplir con requisitos de producción específicos. Esta tecnología de automatización reduce los costos operativos y aumenta la productividad, lo que la convierte en una parte integral de las fundiciones modernas.